PRODUCTS

CATEGORY

GET A QUOTE

If you have any questions, please feel free to contact us.

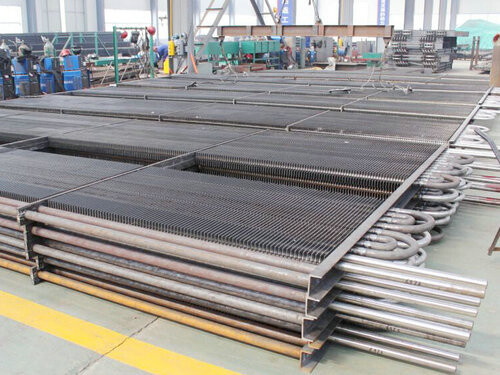

Laser welded finned tube is a new type, wear-resistant and efficient heat exchange material in the finned tube welding industry. It has the characteristics of wide range, high pressure, and compliance with national energy conservation and environmental protection emission standards.

Laser welded finned tubes are widely used in chemical engineering, power, air conditioning engineering, petrochemical engineering, and refrigeration engineering, such as surface air coolers, air heaters, and fan coils used in air conditioning engineering. The equipment is used in refrigeration engineering for air cooler evaporators and frost-free refrigerator evaporators, etc.

Laser-welded finned tubes are not only suitable for the flow of single-phase fluids during use, but their equipment is also of great value for phase transfer heat. Most of the finned tube heat exchangers used for clean gases use The new high-efficiency fin surface structure has obtained a significant heat transfer effect.

Compared with other type of finning processes, laser welding of finned tubes greatly saves material costs to a certain extent, achieves high penetration rate, and can effectively prevent corrosion of its gaps during use, which will effectively extend its length to a certain extent. Reduce the service life of the equipment and reduce its thermal resistance to heat transfer.

In terms of quality control of laser-welded finned tubes, its equipment mainly uses its ccd monitoring system during the production process to monitor the welding area throughout the process, first-piece approval, and use a metal graphic analysis system to obtain the welding status and ensure product quality. Continue production after passing the test.

Material Combination of Laser Welded Fin Tube

Characteristics

1. The thickness of the base tube can be 0.5-5 mm, and the thickness of the fins can be 0.28-1.0 mm, which greatly saves the material cost compared with other processes. The unique winding process can ensure that the fin spacing is at least 2.0mm or less, and the fins are evenly distributed, the bottom is flat and wrinkle-free, which prevents dust accumulation and greatly improves the heat transfer efficiency. Compared with high-frequency welded fins of the same specification The tube should save energy by more than 30%.

2.High penetration rate can prevent crevice corrosion, prolong service life and reduce heat transfer resistance.

3.Breaking through material limitations, different materials can be used for processing.

4.It is easy for secondary processing, and can be directly coiled and bent.

5.The welding heat affected zone is small and the metallographic change is small, which makes it possible to process small diameter finned tubes.

6. The degree of automation is high. The fully automatic fin laser welding machine can realize one-time welding, and the synchronous winding of the fins makes the fin feet and the pipes deeply welded. 100% welding between fins and tubes, no filler material used. Since the laser welding is performed under a protective atmosphere, there are no impurities on the weld seam.

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

Jiangsu Hailiang Dongfang Import and Export Co., Ltd specializes in heat exchanger tubes and finned tubes, including aluminum tube, carbon steel tubes, stainless steel tubes, nickel alloy tubes, copper tubes and a wide range of finned pipes (Bi-metal Composited Fin Tube, Extruded Fin Tube, L Foot Fin Tube, LL Fin Tube, KL Fin Tube, Embedded G Fin Tube, Integral Low fin tube, corrugated tube, High Frequency Fin Tube, Laser Welded Fin Tube). The tubes are applied in air preheater, boiler, shell and tube heat exchanger, air cooled heat exchangers, evaporator and other heating recovery system.

We have advanced R&D department for production process, equipment design etc. Our annual pipe capacity reach 60000MT high precision cold drawn tube, 200000 MT seamless pipe and 40000MT hydraulic cylinder rod. Our products are widely used in petroleum, natural gas, chemical industry, construction, geological and automobile industry.

Product standardization

We are committed to comprehensive standardization of our products, ensuring sufficient stock, diverse models, and comprehensive coverage. Each product has undergone strict screening, with excellent quality and trustworthiness.

Standardization of processes

With strong technical strength and advanced production technology, we have achieved complete standardization of the process. This not only ensures the accuracy and stability of the product, but also demonstrates our professionalism and strength in the manufacturing field.

Service standardization

We adhere to standardized service, providing fast and timely delivery, meticulous and thoughtful service, and worry free after-sales support, so that you can feel our dedication and commitment in every cooperation.