PRODUCTS

CATEGORY

GET A QUOTE

If you have any questions, please feel free to contact us.

The aluminum fin strip or the copper fin strip is folded into an L shape and spirally wound tightly

under the action of tension on the outer surface of the base tube. Tension in the fin strip is

wrapped around the tube serves to make the fin foot forcefully on the tube, thus hold the fin

firmly in place.

L foot tension finned tubing is combined with two different materials

Core Tube: Carbon steel, stainless steel, copper

Fins: Aluminum, copper

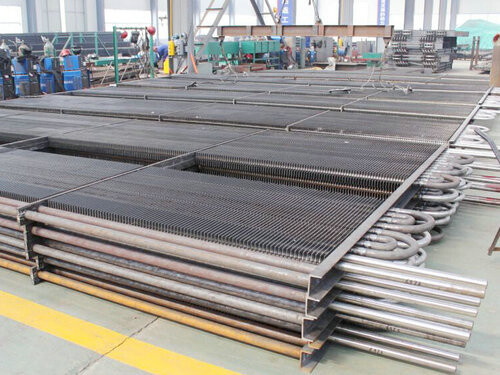

Features of L Foot tension finned tubing: low cost, high production efficiency, uniform sheet distance, good heat transfer performance, good vibration resistance, high finning ratio, and the substrate tube can be protected from air erosion.

Application: Mainly used in protein powder, starch, soybean milk powder, maltodextrin, vegetables, food, pharmaceuticals, paper making, coal washing and transformers, dyeing and weaving, ceramics, leather, textiles, electric power, refrigeration, tobacco, plastics, grain and oil, petroleum , air coolers in the chemical industry and industrial and civil air heaters and radiators.

This is a circular fin wrapped helically around the tube under tension. Full coverage of the base tube by the L-foot offers good protection against atmospheric corrosion.

These fins tend to become loose over time, resulting in significant deterioration in the air side performance due to the gap between the tube and the fins. Consequently, their use is limited to applications where the process-fluid inlet temperature is less than 120℃. However, the majority of ACHE applications have process inlet temperatures less than this.

Since the air side performance of these finned tubes is likely to deteriorate due to the loosening of the fins. They are generally not very popular. One place where they are common is in the corrosive marine atmospheres of offshore platforms. Since they afford good protection against

Atmosoheric corrosion of the base tubes and are superior to grooved fins.

Dimensions

Base Tube: SA179 Tube, Copper Tube, Stainless Steel Tube, Alloy Tube

Fin Material: Al1100, Al1060, Copper Strip

Base Tube OD: 1’’to 2’’

Tube length: no limit

Fin OD: 2 1/4’’ to 3 1/4’’

Fin Pitch: 4FPI to 12FPI.

Cangyang Thermal Energy has 5 production lines for Embedded G Fin, also available for producing L Fin, LL Fin Tube and KL Fin Tube. Production capacity is 5000meters per day.

To avoid any mistanderstanding on your enquiry, we request you to provide the following datas.

Core Tube (Base Tube) Material and Quantity

Base Tube OD * tube wall thick * length

Fin Type and Fin Material

Fin Dimensions: Fin OD * Fin Thick * Fin Pitch * Unfinned Length at two sides

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

Jiangsu Hailiang Dongfang Import and Export Co., Ltd specializes in heat exchanger tubes and finned tubes, including aluminum tube, carbon steel tubes, stainless steel tubes, nickel alloy tubes, copper tubes and a wide range of finned pipes (Bi-metal Composited Fin Tube, Extruded Fin Tube, L Foot Fin Tube, LL Fin Tube, KL Fin Tube, Embedded G Fin Tube, Integral Low fin tube, corrugated tube, High Frequency Fin Tube, Laser Welded Fin Tube). The tubes are applied in air preheater, boiler, shell and tube heat exchanger, air cooled heat exchangers, evaporator and other heating recovery system.

We have advanced R&D department for production process, equipment design etc. Our annual pipe capacity reach 60000MT high precision cold drawn tube, 200000 MT seamless pipe and 40000MT hydraulic cylinder rod. Our products are widely used in petroleum, natural gas, chemical industry, construction, geological and automobile industry.

Product standardization

We are committed to comprehensive standardization of our products, ensuring sufficient stock, diverse models, and comprehensive coverage. Each product has undergone strict screening, with excellent quality and trustworthiness.

Standardization of processes

With strong technical strength and advanced production technology, we have achieved complete standardization of the process. This not only ensures the accuracy and stability of the product, but also demonstrates our professionalism and strength in the manufacturing field.

Service standardization

We adhere to standardized service, providing fast and timely delivery, meticulous and thoughtful service, and worry free after-sales support, so that you can feel our dedication and commitment in every cooperation.