PRODUCTS

CATEGORY

GET A QUOTE

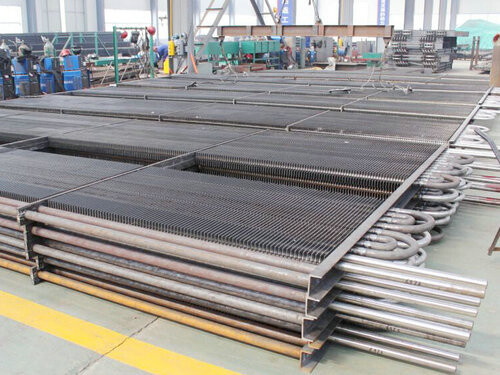

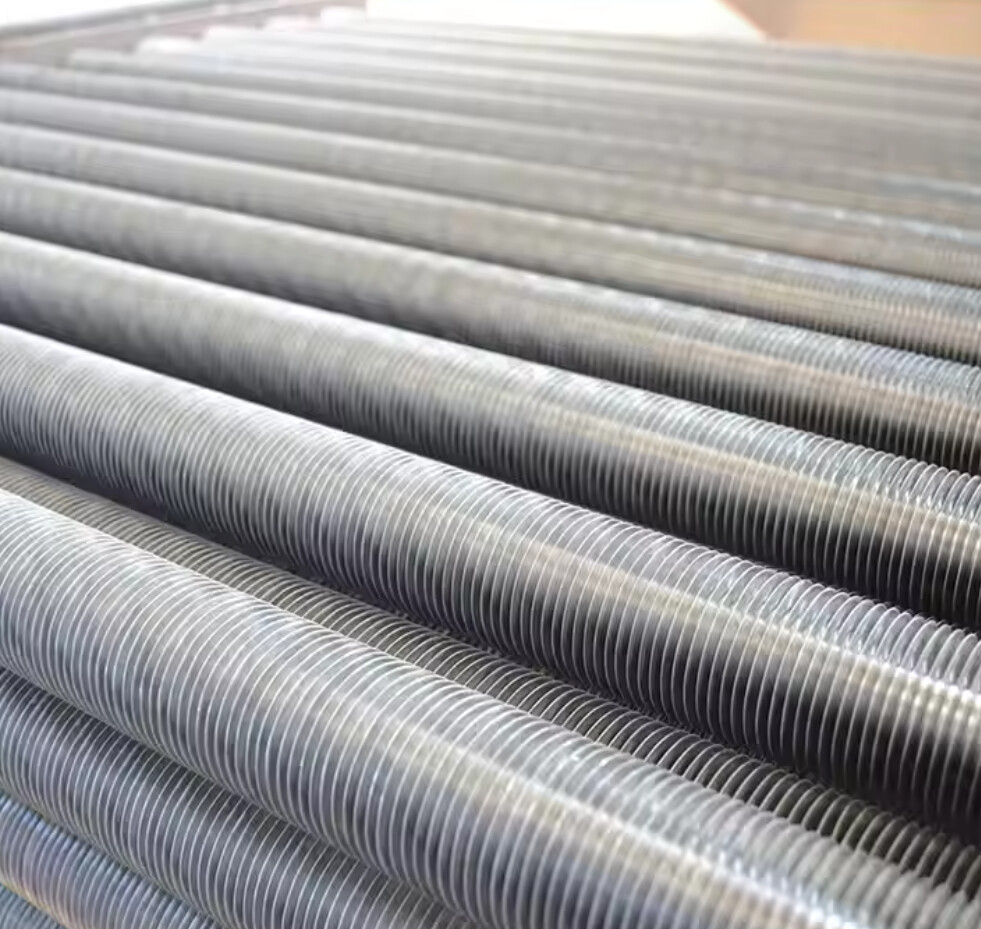

What is G Fin Tube

G type fin tube, also known as embedded finned tube, where g means slotted. It is formed by screwing fin strips made of copper or aluminum into machined grooves and backfilling to secure the lock. Fill the base tube material. Compared with other finned tubes, G type fin tubes are firmer. Therefore, it is widely used in places where high-temperature heat transfer is required. The G type fin tube is a circumferential finned tube in which the fin is mechanically embedded in the groove, the groove is plowed into the tube, and the roller is locked in place, thereby forcing the groove to tightly surround the fin base.

Advantages of G Fin Tube

1.High production efficiency, continuous winding production;

2.Low cost. It relies on the characteristics of high-frequency welding itself-skin effect to heat the surface of the workpiece to achieve the purpose of welding firmly, without adding any filler metal material during the welding process;

3.Since the high-frequency current only passes through the shallow surface of the steel pipe, the welding heat-affected zone is small, so the additional wall thickness caused by this need not be considered in the design calculation; the workpiece does not need to be heat treated after welding;

4.The welding is reliable, can withstand the thermal shock fluctuation caused by frequent opening and shutdown.

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

Jiangsu Hailiang Dongfang Import and Export Co., Ltd specializes in heat exchanger tubes and finned tubes, including aluminum tube, carbon steel tubes, stainless steel tubes, nickel alloy tubes, copper tubes and a wide range of finned pipes (Bi-metal Composited Fin Tube, Extruded Fin Tube, L Foot Fin Tube, LL Fin Tube, KL Fin Tube, Embedded G Fin Tube, Integral Low fin tube, corrugated tube, High Frequency Fin Tube, Laser Welded Fin Tube). The tubes are applied in air preheater, boiler, shell and tube heat exchanger, air cooled heat exchangers, evaporator and other heating recovery system.

We have advanced R&D department for production process, equipment design etc. Our annual pipe capacity reach 60000MT high precision cold drawn tube, 200000 MT seamless pipe and 40000MT hydraulic cylinder rod. Our products are widely used in petroleum, natural gas, chemical industry, construction, geological and automobile industry.

Product standardization

We are committed to comprehensive standardization of our products, ensuring sufficient stock, diverse models, and comprehensive coverage. Each product has undergone strict screening, with excellent quality and trustworthiness.

Standardization of processes

With strong technical strength and advanced production technology, we have achieved complete standardization of the process. This not only ensures the accuracy and stability of the product, but also demonstrates our professionalism and strength in the manufacturing field.

Service standardization

We adhere to standardized service, providing fast and timely delivery, meticulous and thoughtful service, and worry free after-sales support, so that you can feel our dedication and commitment in every cooperation.