PRODUCTS

CATEGORY

GET A QUOTE

If you have any questions, please feel free to contact us.

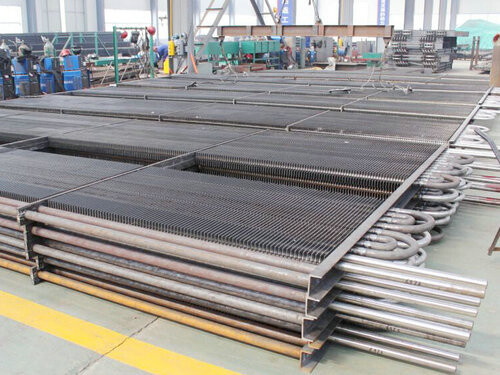

Crimped Fins are spirally wrapped onto the base tube without welding, but spot welded at two ends. The steel strip can be copper, carbon steel, stainless steel. Non-ferrous tubes and fins on either root soldered or completely tinned.

Material Standard

Both base tube and fin can be copper, carbon steel and stainless steel

Carbon Steel: A179, A192,SA210 Gr A1/C,A106 Gr B

Stainless Steel: TP304/TP304L

Copper strip also available.

Maximum working temperature: 120°C

Our spiral crimped finned tubes is with base tubes of carbon steel, stainless steel, copper and copper alloys such as admiralty brass, aluminum brass with copper fins, staninless steel fins and zinc galvanized fins. The base tube of standard edge wound crimped fin tubes range from 15.875mm to 50.8mm with fin height ranging from 10mm to 15mm.

For this kind of crimped fin tubes, the fin pitch is around 5-6FPI. (large fin pitch than other aluminum fin types).

Below Chart of spiral crimped fin tubes dimensions for your reference.

Features

Uniform pitch

Small fold on fins

Tubes and fins are connected tightly

No ash accumulation

High heat transfer capability

Maximum working temperatures: 120°C

Since the stainless steel is with high corrsion resistance, the stainless steel crimped fin tube can be widely used when the circumstance has a certain degree of corrosion or cleanliness, such as climatic industry, heating, drying and cooling. Stainless steel tube with helical SS304 fins is widely applied in wood drying kilns to dry the woods.

Jiangsu Hailiang Dongfang Import and Export Co., Ltd.

Jiangsu Hailiang Dongfang Import and Export Co., Ltd specializes in heat exchanger tubes and finned tubes, including aluminum tube, carbon steel tubes, stainless steel tubes, nickel alloy tubes, copper tubes and a wide range of finned pipes (Bi-metal Composited Fin Tube, Extruded Fin Tube, L Foot Fin Tube, LL Fin Tube, KL Fin Tube, Embedded G Fin Tube, Integral Low fin tube, corrugated tube, High Frequency Fin Tube, Laser Welded Fin Tube). The tubes are applied in air preheater, boiler, shell and tube heat exchanger, air cooled heat exchangers, evaporator and other heating recovery system.

We have advanced R&D department for production process, equipment design etc. Our annual pipe capacity reach 60000MT high precision cold drawn tube, 200000 MT seamless pipe and 40000MT hydraulic cylinder rod. Our products are widely used in petroleum, natural gas, chemical industry, construction, geological and automobile industry.

Product standardization

We are committed to comprehensive standardization of our products, ensuring sufficient stock, diverse models, and comprehensive coverage. Each product has undergone strict screening, with excellent quality and trustworthiness.

Standardization of processes

With strong technical strength and advanced production technology, we have achieved complete standardization of the process. This not only ensures the accuracy and stability of the product, but also demonstrates our professionalism and strength in the manufacturing field.

Service standardization

We adhere to standardized service, providing fast and timely delivery, meticulous and thoughtful service, and worry free after-sales support, so that you can feel our dedication and commitment in every cooperation.